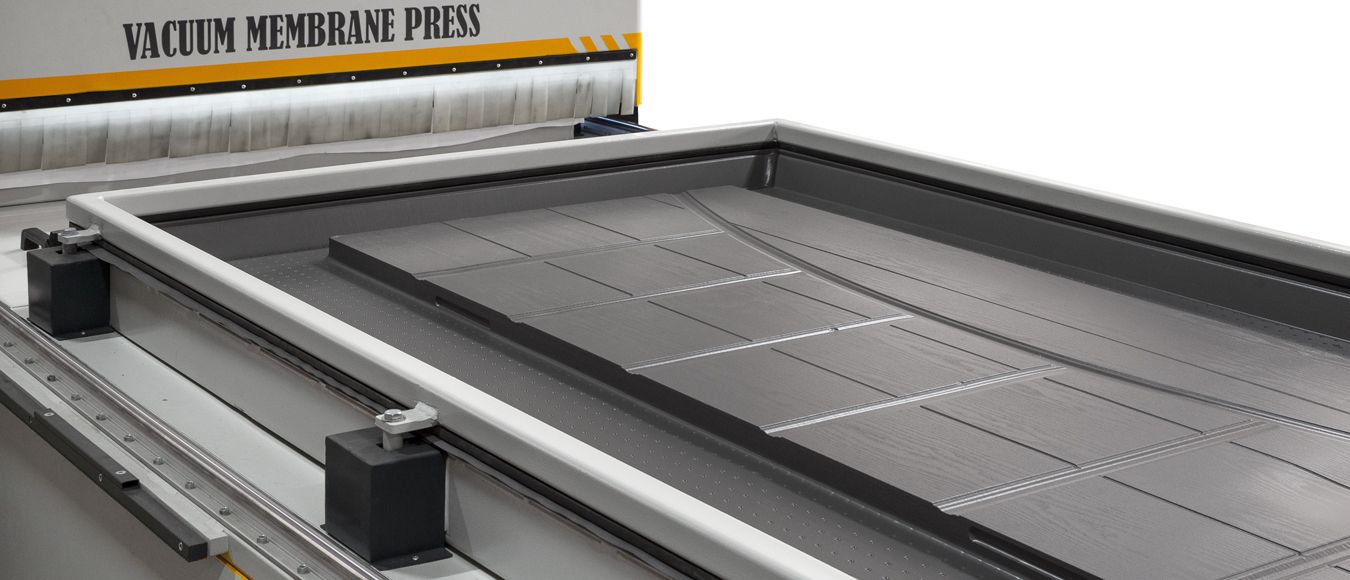

THE 2123 Thermoform Machine

Thermoforming Machines and Their Applications

Thermoforming machines are significant industrial equipment that enables the shaping of thermoplastic materials through heating and subsequent molding processes. These machines have a wide range of applications across various industrial sectors, facilitating the shaping of various materials, especially plastics, into desired shapes and sizes.

What Can Be Produced?

Packaging Materials: Thermoforming machines are used to produce plastic trays, blister packaging, bubble packs, and other packaging solutions. They provide durable and hygienic packaging used in various sectors from the food industry to medical devices.

Automotive Parts: In the automotive sector, many parts such as interior trim parts, console panels, door panels, and other interior components are produced using thermoforming machines. These parts are often made from plastic materials and meet specific design and durability requirements.

Medical Device Components: Many medical devices have specialized parts produced using thermoforming machines. These include surgical instruments, medical blister packaging, respiratory device components, and more. Special materials can be used to meet sterilization requirements for these parts.

Electronic Components: The electronics industry relies on many parts produced with thermoforming machines. Plastic casing parts, card enclosures, mounting sockets, and other components are used in the assembly of electronic devices. These parts are designed to meet insulation, durability, and other special requirements.

Building Materials: Some thermoplastic materials can be used for various applications in the construction sector. Thermoforming machines can be used to produce wall coverings, suspended ceiling panels, window frames, and other structural components. These parts are often lightweight, durable, and easily cleanable.

Thermoforming machines play a significant role in industrial production processes and provide flexibility in the production of various products used across different sectors. With the use of these machines, custom-designed parts can be produced quickly, enhancing production efficiency.

Our company specializes in thermoforming machines and a variety of products that can be produced using these machines. Feel free to contact us for customized solutions tailored to your needs.

Please contact us to get detailed information about Thermoform Machine prices and specifications.

| PROFESSIONAL PACKAGE | THECNICAL SPECIFICATIONS |

| TABLE | 1060X2300 / 1060X2300 / SPECIAL DIMENSION |

| HEATING SYSTEM | 190V 600 W 620 MM R |

| VACUUM SYSTEM | 111 M³ / H |

| HEATING SENSOR | IR LASER HEATING SENSOR |

| LOADING UNIT | STANDARD |

| MOLD SYSTEM | SPECIAL PRODUCTION |

| ALERT SYSTEM / PROTECTION SYSTEM | BUZZER / EMERGENCY STOP |

| OPERATING PANEL | 7 " TOUCH PANEL |

| ELECTRIC & ELECTRONIC SYSTEM | PROFESSIONAL / GERMANY |

| MOTORS | 0.37 KW 1/15 S40 |

| HELICAL RACK SYSTEM | MOD2 |

| OPERATION TIME | 1-4 MIN |

| TOTAL WEIGHT | 1650 Kgs |

| DIMENSION | 1310 x 1450 x 5500 |

| COOLING SYSTEM | TURBO FAN COOLING SYSTEM |

| TOTAL ENERGY CONSUMPTION | 34 KW |

| TOTAL ENERGY CONSUMPTION | 8 BAR |